Jewelry Repair in Colorado Springs, CO

Here at Berges Jewelry Design we are a full service jewelry store which is a rarity. We are able to repair and design jewelry here in our manufacturing facility.Our design techniques are extensive, Mark was one of the first adopters in the jewelry industry to use CAD technology (Computer Aided Design) to design 3-dimensional images. We are also still able to honor old world wax carving techniques and traditional hand fabrication. Using art and science we will create a quality design of your dreams. With all custom designs you have the ability to be involved from start to finish, ensuring you are getting exactly what you are wanting. If it can physically be done we will be able to create it.

Custom Jewelry Design in Colorado Springs, CO

Design Consultation

During the design consultation you will meet with one of our designers. At this meeting feel free to bring in any ideas you have. Did you get inspired from picture you've see or flower in a garden? Whatever it may be we would love to help you dreams come true.

Don't have any pictures or ideas? that's OK! Many clients have no idea exactly what they want they are just wanting a one of a kind piece. Our designer's are always helping to create that unique design you are after.

Do you have old jewelry laying around? Or did you inherit jewelry that's just not your style? Bring it in and we can recreate/re-design it for you. There is great value in diamonds and gemstones let us design something for you using those. You'd be surprised with all we can do with the pieces most people have pushed to the back of their jewelry boxes. Imagine wearing grandma's old diamonds from her wedding set in your new favorite jewelry piece that's a style that you love and can be enjoyed for many years to come.

Rendering

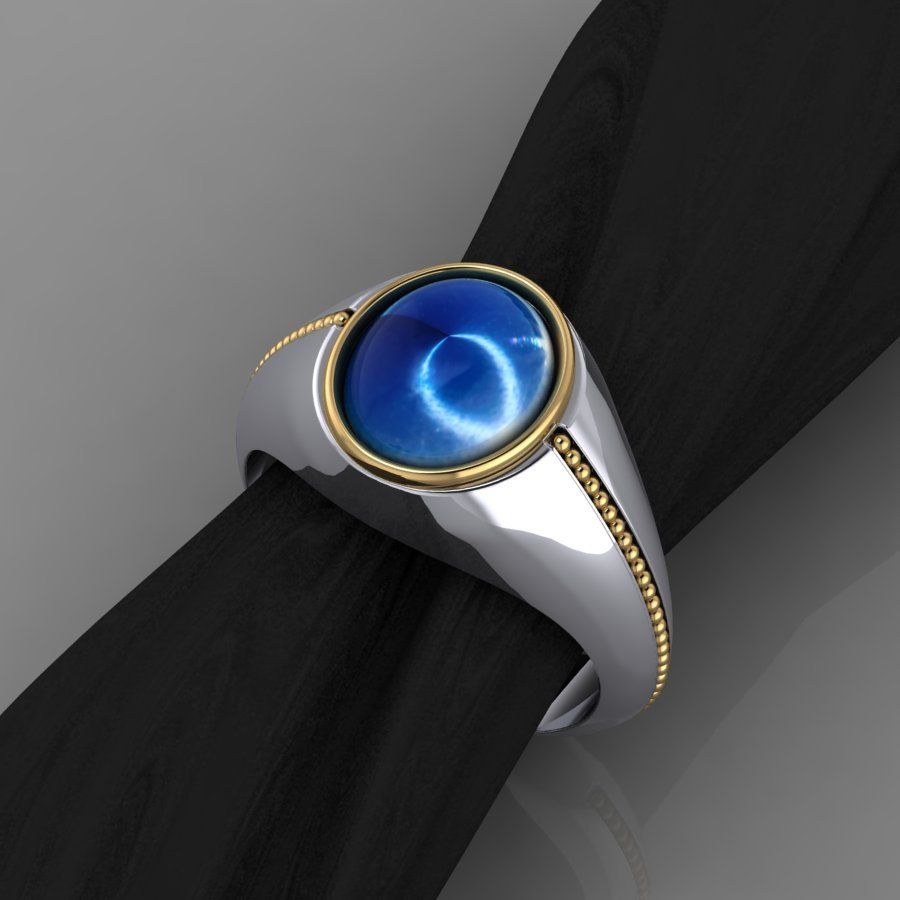

At this stage you get to see the start of your dreams turn into a designed piece of jewelry. At this step we have created a 3-D image for you to come in a view to see every angle of it and make sure the proportions are just what you wanted.

Can't decided if you want your piece in yellow or white gold? Did you want diamonds or sapphire on the side of you center diamond? All of these options can seem hard to make at times. The wonderful thing about our state of the art design technology we use is we are able to show you these different options so you can see side by side comparisons and feel better about your choice.

Once the 3-D renderings are perfect and approved by you we move forward with the next step in the design process.

Cad/Cam wax model

The wax step is where we take the approved rendering to be either carved or grown out of wax. After the mill has cut the wax model the client can again come into the store to see a actual real life model of the design. At this point you are able to get a even better visual of your custom made piece. Clients love this stage because it's their actual piece of jewelry that will get approval and be invested and cast into metal form.

Are you wanting to add more diamonds to the ring once you see the model now? Or did you want to change the design a little bit for some reason? Don't worry changes can still be made if needed and a new wax can be formed. That's the wonderful thing about working with us on a custom design is we want you to be involved as much as you want and if changes need to be made we can do it. Your never going to be surprised at pickup thinking you were wanting it designed one way and we didn't understand that. Since your involved every step of the way there's never any upsetting surprises on the day of delivery.

Casting

Lost wax casting is truly an art that is still used. In this step we take the approved wax model and invest it ensuring every little detail will come out in metal form. The invested wax is then put into a kiln to burn out the wax over several hours and you are left with impression in the investment containing every little detail that is making you piece a true one a kind piece of jewelry. After the wax is burned out we take that to the casting unit and turn the precious metal into a liquid metal form using a torch and high heat. Once the metal is in liquid form it is then poured into the molded investment. The metal cools down a bit and within minutes your wax model is now in metal form.

Yes, for those who are fascinated by this step and want to be involved we are able to cast your piece while you watch if you make a appointment.

Not interested in watching this happen? That's perfectly fine we can do this step without you involved.

Stone Setting

After the casting the precious metal will have a matte finish on the surface. Lots of hand work of polishing of the metal to bring the precious metal to a shiny finish. Jewelry pieces are put through many polishing and detailing steps to get to the finished stage. After the metal is ready stone setting or final detailing begins.*

*If at this point you were perhaps wearing your diamonds and gemstones in another piece of jewelry we will have you bring them in so we can set the stones into your new custom made jewelry piece. This is especially helpful to our patrons if we are creating a remount for them and they didn't want to be with out their jewelry for to long.